Proofing

Printing paper to be used within the industry of melamine boards means large-scale production.

Melamine market is a huge market. The average production is around 3 million square meters per month. Printing such a huge volume is something that ought to be developed within an industrial environment. Therefore, the impact of innovation in this field is very relevant. Nevertheless, there are issues related to this large-scale production, which represent an added difficulty. The printer ought to work nonstop, but at the same time the quality control needs measurements and new design should enter into production every day. Interrupting the production for any of those reasons would be very expensive. Because of this, proofing is needed to control the quality of the color.

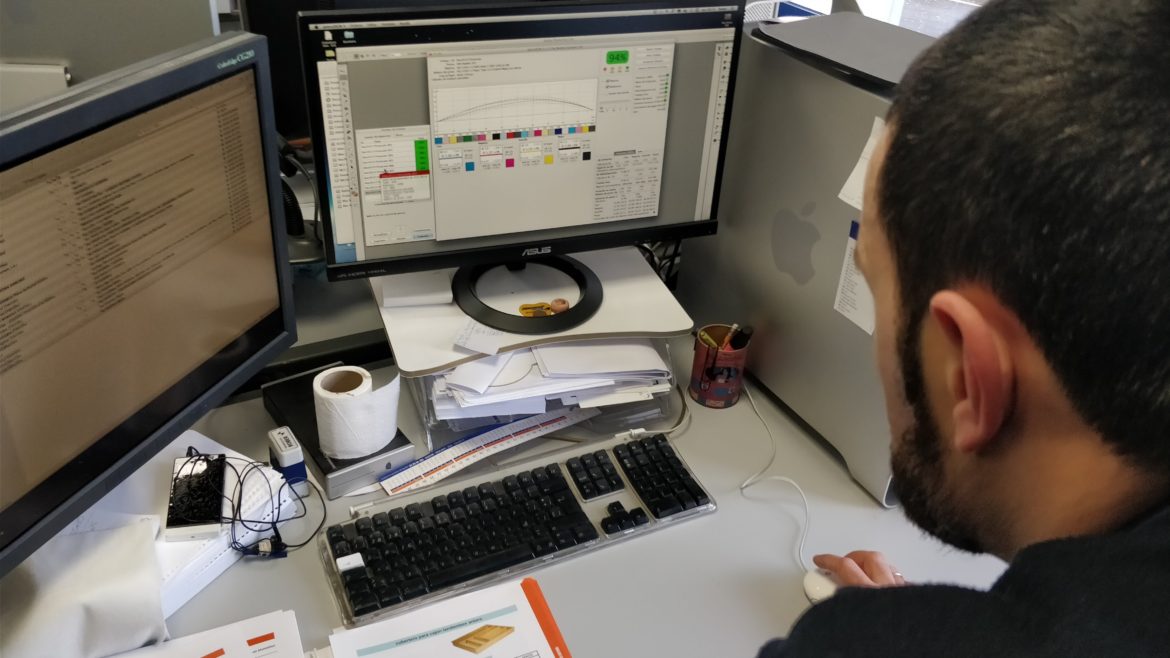

SEISTAG designed the proofing technology for PRINTODECO Project. The technological Company proposed a technical solution similar to the one used for large-scale offset production, but this time used not to control an analogical printing device, but a large-scale digital printer. Proofing means printing trials in a small printer in order to keep the big one running nonstop and error free. It is very usual for large-scale production. It is also typical when color is an important element in the image.

Proofing needs profiling the industrial printing device. This is done in three steps. The first step is to measure the real color produced by the printer. Then to compare it with the theoretical color of the original image. Finally, establishing a mathematical relationship between the coordinates of the color to be printed and the coordinates of the printed color. A line describes that relation, and that is the reason why it is called profile. Moreover, as there are four channels of color (Cian, Magenta, Yellow, and Black), four profiles are needed.

Once the industrial partner has been described by means of its profiles, it is possible to print at lab scale as if it were the industrial printer. Note that the lab scale printer should be able to reproduce more colors than the industrial printer. Otherwise, the lab-scale printer would not be able to reproduce the results of the industrial device: a high-quality printer at the laboratory is necessary. Luckily TORCULO owns a machine that suits this need. This enabled proofing during the PRINTODECO Project, which was a technical process to ensure quality steered by SEISTAG within PRINTDECO Project.