Printodeco video is up

Since November the 14th, the video of Printodeco is available at YouTube. The collaboration of all partners, and especially through the effort of Torculo and Seistag, made possible the video.

The video was recorded in summer 2018. It demonstrates the achievements of the Partnership of Printodeco Project. This is a collaborative project among four Spanish Companies. The project focused on reducing time to market of design products enabling enhanced possibilities for customization to the customers.

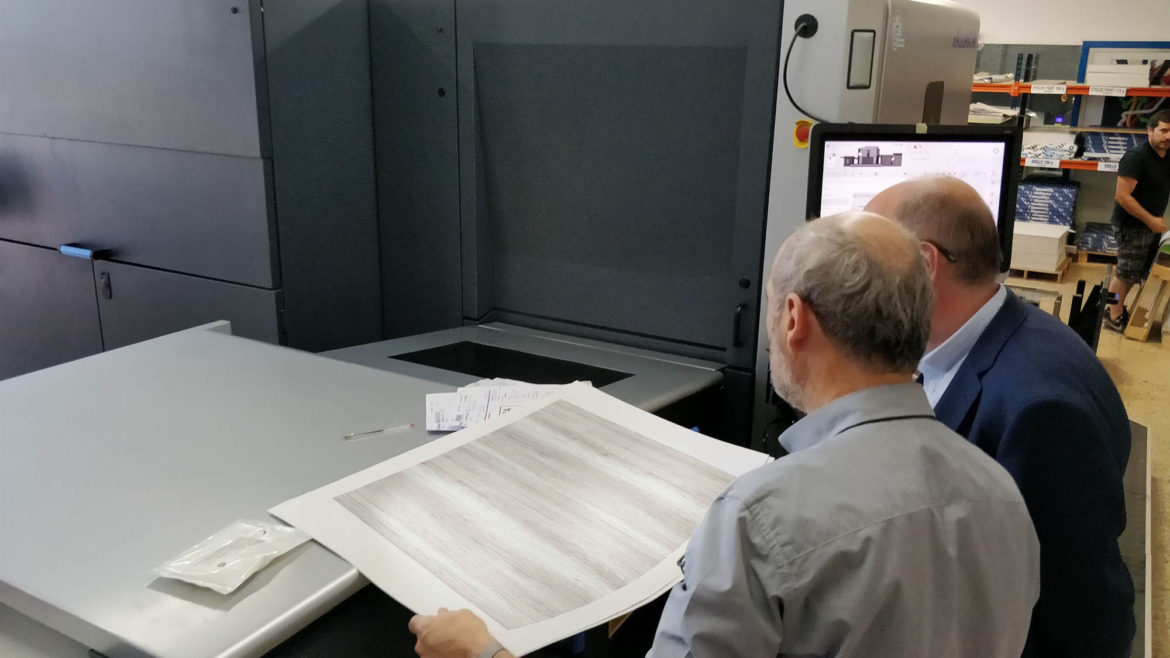

The video shows the way in which a designer can define a decorative pattern and, in just 48 hours, that design becomes a piece of furniture. This is possible thanks to the collaboration of technicians, printers, board makers and furniture makers. In order to make it happen, different resources are needed:

One of the tools is the catalog of ready to print designs. It is a printed booklet, but also a website which enables changing many parameters to the default images. By means of this, the customization possibilities are countless and the designer is not forced to start from scratch.

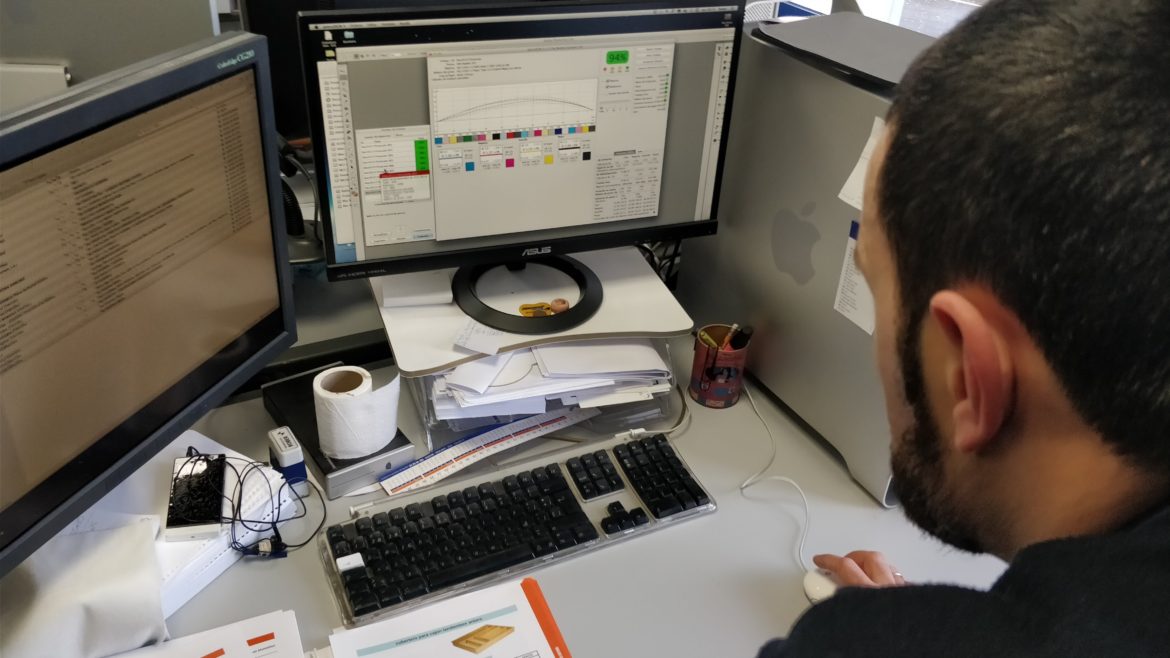

A second tool is a workflow, which compromises the whole Consortium. It ensures the quality of the images and also of the printing process. Special inks and papers are used and everything is done under special codes to ensure that the paper will fit the boards.

Thanks to the above-mentioned tools, making melamine boards and furniture with the printed paper is a standard process with no extra costs. Thanks to this, the offer of Printodeco can be cost-effective and therefore competitive in a huge market.