at RUBRICA magazine

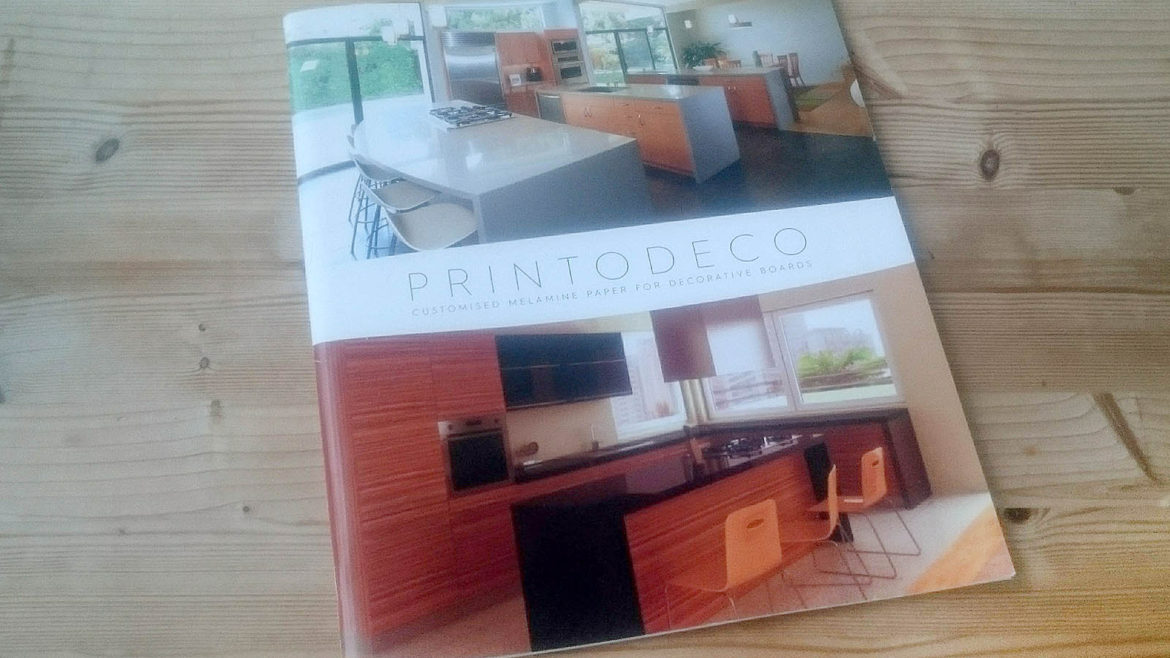

The last number of RUBERICA magazine shows many details of PRINTODECO Project. The current issue is number eight and it offers a two-page review on the Project development, its objective and the most relevant facts.

The magazine target are private companies and industries who want to be updated to the state of the art of design, communication strategies and marketing actions. In this context, PRINTODECO is interesting as it will provide fully customized products and shows in a very clearly manner, the huge possibilities of product personalization by means of digital printing.

Therefore, the review of PRINTODECO project at RUBRICA magazine focuses on the possibilities of the digital printing. From one hand, it presents the possibilities of innovative products such as melamine boards. From the other it suggests a revolution concerning the relation between customer and producer.